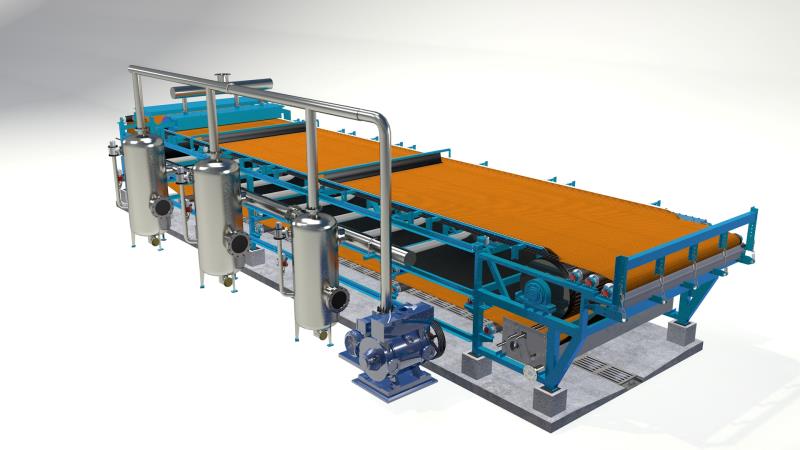

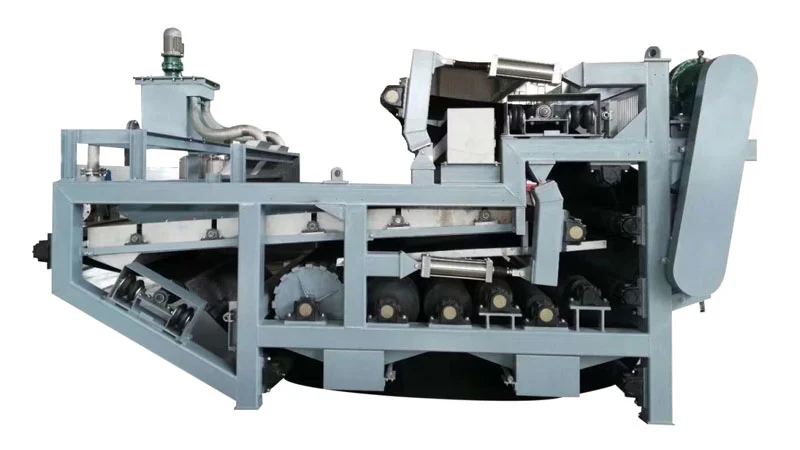

Horizontal Vacuum Belt Filter Working Principle

Vacuum Negative Pressure Principle

Horizontal vacuum belt filter working principle is that under the action of vacuum negative pressure (0.04-0.07 MPa), the liquid in the suspension passes through the filtration medium (filter cloth) and is drawn away, while the solid particles are retained by the medium, thus achieving the separation of liquids and solids.

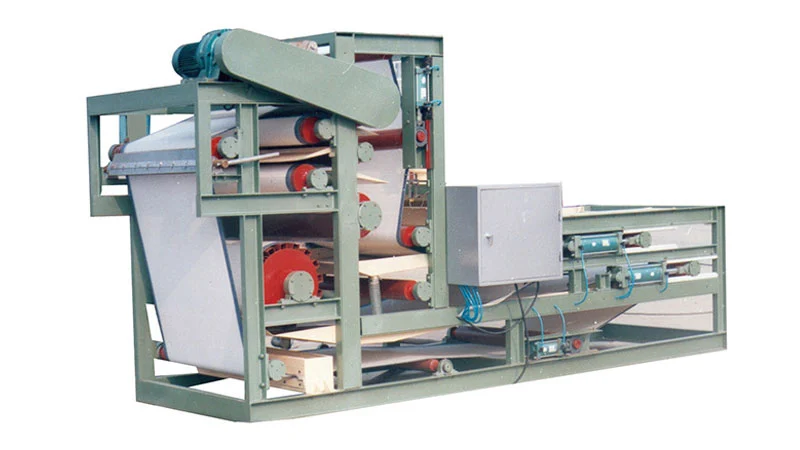

Role of Filtration Medium

Horizontal vacuum belt filter working principle applies surface filtration mechanisms. When the liquid from the suspension flows towards the filtration medium, solid particles larger than or close to the size of the filtration medium’s pores will initially form a layer on the surface of the medium in a bridging manner. Since the pores of the filtration medium are larger than the pore channels, this retains smaller particles.

Formation and Accumulation of Filter Cake

As the filtration process continues, the solid particles that continuously deposit will gradually form a filter cake with a certain thickness on the initial deposition layer. This process will affect the filtration speed and efficiency.

Negative Pressure Driven Filtration Process

The horizontal vacuum filter creates negative pressure at the filtrate outlet as the driving force for filtration. This negative pressure driving method effectively promotes the liquid’s passage through the filtration medium, while retaining the solid particles.

Batch and Continuous Operation Modes

The horizontal vacuum belt filter is available in two operation modes: batch operation and continuous operation. Batch operation is suitable for filtering suspensions of various concentrations, while continuous operation is suited for suspensions containing more solid particles.

Applications of Horizontal Vacuum Belt Filter

The vacuum belt filter is a highly automated, new type of filtration equipment. It is widely used in industries such as thermal power, chemicals, pharmaceuticals, papermaking, building materials, metallurgy, rubber, and food.

Future Prospects of Horizontal Vacuum Belt Filter

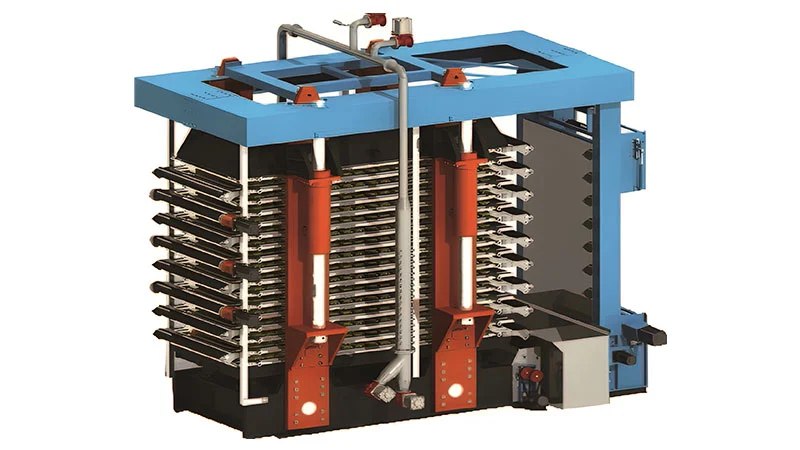

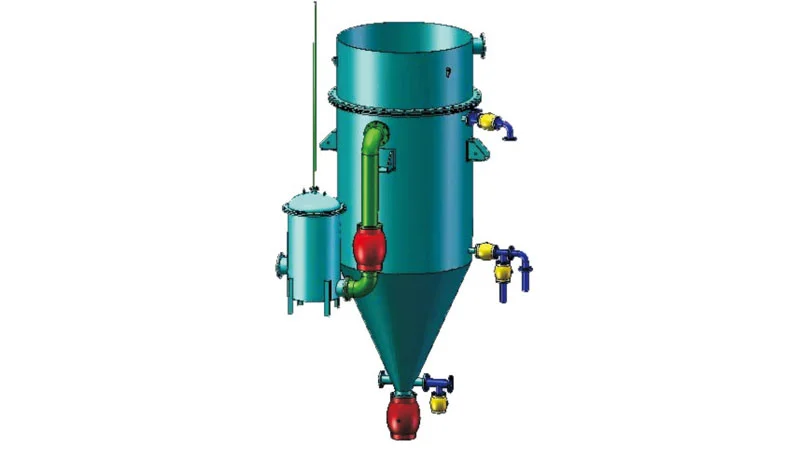

Developing new types of filtration equipment include mechanical pressure squeezing filters, dynamic filters capable of achieving filtration without a filter cake layer, and large-scale filtration equipment used for washing coal wastewater treatment, chemicals, and petroleum industries.

In terms of filtration theory research, important topics include the calculation of filter cake resistance and porosity, filtration speed, simulation and scaling of filtration equipment, clarification filtration of thin liquids, dynamic filtration mechanisms, and studies on filtration media. The use of electronic computers to control filtration operations is the direction for the future development of filtration equipment.

Hesheng Filter

Hesheng Filter

Call us on:

Call us on:  Email Us:

Email Us:  No.255 Shenzhen North Road, Laixi City, Qingdao City, Shandong P.R, China

No.255 Shenzhen North Road, Laixi City, Qingdao City, Shandong P.R, China