In modern industrial production, the separation and purification of materials are crucial steps. The horizontal vacuum belt filter, with its efficient and stable performance, has become an indispensable piece of equipment in many industries. Today, let's dive into the mysteries of the vacuum belt filter.

Working Principle

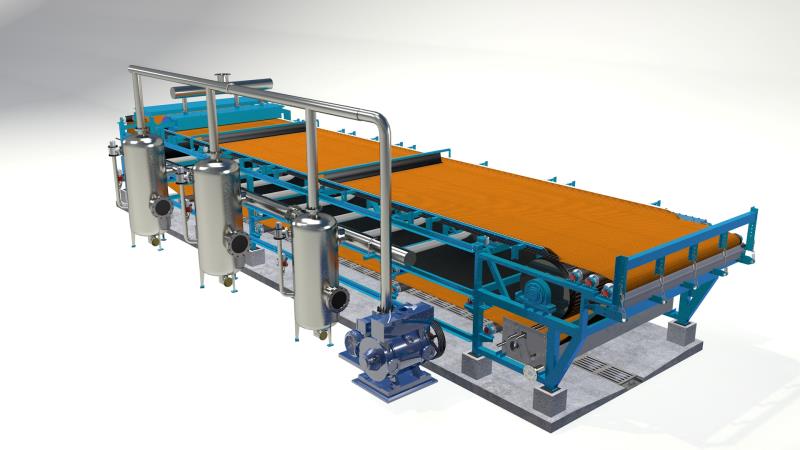

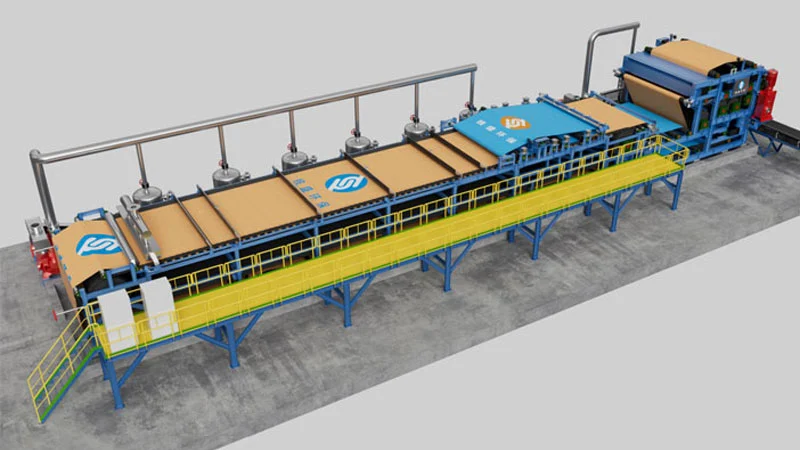

The core principle of the horizontal vacuum belt filter is based on vacuum suction. When the material is evenly spread on the filter belt, under the action of vacuum suction, the filtrate passes through the filter cloth into the vacuum chamber, while solid particles are retained and form a filter cake. As the filter belt continuously operates, the filter cake is gradually conveyed to the discharge end for removal, thereby achieving effective solid-liquid separation. This continuous operational mode enables high efficiency and stability in handling large quantities of materials, greatly improving production efficiency.

Structural Components

Filter Belt: This is one of the key components of the horizontal vacuum belt filter, usually made of high-strength, corrosion-resistant materials such as polyester and polypropylene. The weaving method and pore size of the filter belt are customized according to different filtration needs to ensure that solid particles are effectively retained while allowing smooth passage of the filtrate. Its excellent flexibility and wear resistance ensure reliability and stability in long-term operation.

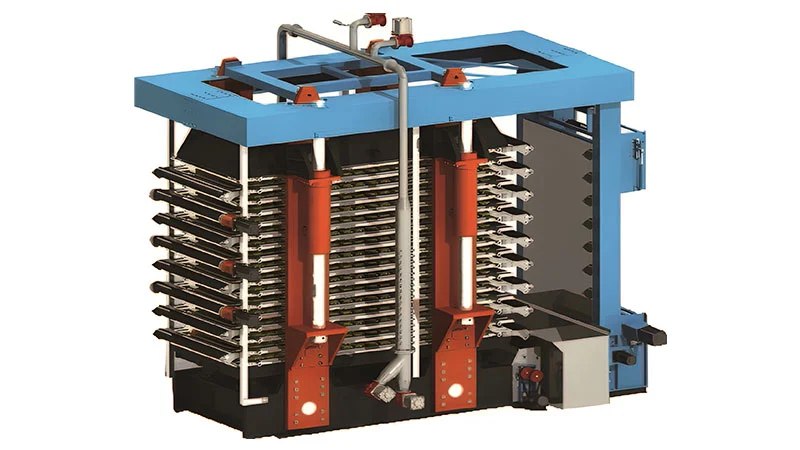

Vacuum Chamber: The vacuum chamber is located below the filter belt, connected to a vacuum pump through piping to form a negative pressure environment. Its seal is critical, directly impacting the vacuum suction effect and filtration efficiency. High-quality sealing materials and precise manufacturing processes are generally used to ensure a stable vacuum level during operation, providing strong support for rapid filtrate suction.

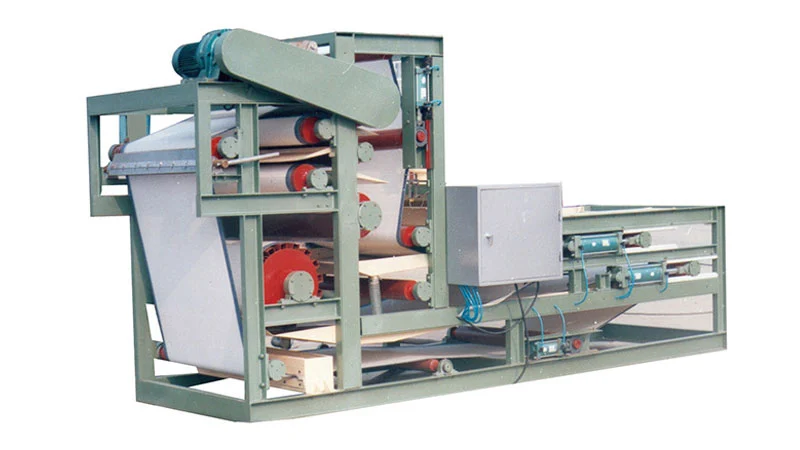

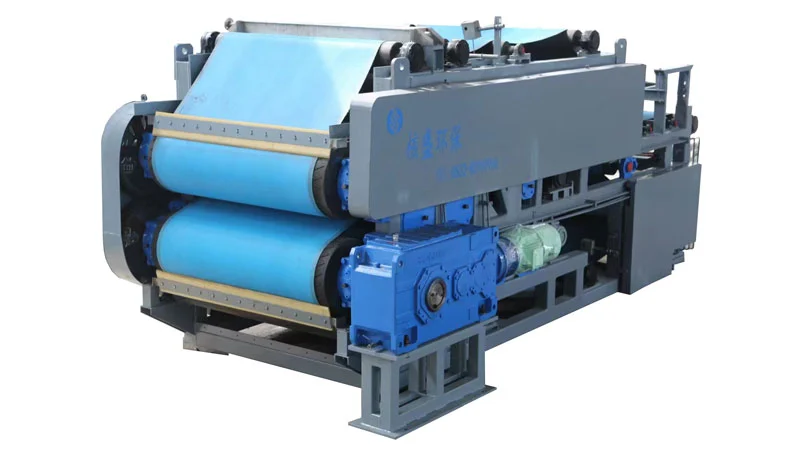

Drive System: The drive system is responsible for circulating the filter belt and includes components such as motors, reducers, and drive rollers. Through precise speed control, the operating speed of the filter belt can be flexibly adjusted according to the nature of the material and filtration requirements, optimizing filtration effects and production capacity, and ensuring a smooth and orderly filtration process.

Cleaning Device: To ensure the continuous efficient operation of the filter belt, the filter is equipped with a cleaning device. After discharge, high-pressure nozzles are used to wash the filter belt, removing residual filter cake and impurities, restoring good filtration performance, and preparing for the next filtration operation.

Advantages and Highlights

High-Efficiency Filtration Performance: The horizontal vacuum belt filter can adapt to various types of materials. Whether dealing with fine-grained suspensions or materials with certain viscosity, it can achieve efficient solid-liquid separation. Its high filtration speed and excellent separation accuracy effectively reduce material loss and improve product recovery rates, bringing significant economic benefits to enterprises.

High Degree of Automation: Modern horizontal vacuum belt filters are equipped with advanced automation control systems that enable remote monitoring and operation. From controlling the feed quantity, adjusting filtration process parameters, to automatic execution of discharge and cleaning, the entire process is highly automated, greatly reducing manual intervention, lowering labor intensity and human costs, and improving the stability and reliability of the production process.

Energy Saving and Environmental Protection: In terms of energy consumption, by optimizing the vacuum system design and using energy-efficient motors, the vacuum horizontal belt filter ensures efficient operation while effectively reducing energy consumption. Additionally, its enclosed filtration structure minimizes the evaporation and leakage of materials and filtrates, thus reducing environmental pollution. This aligns with modern industrial requirements for energy-saving and environmental protection, helping enterprises achieve sustainable development.

Small Footprint: Compared to some traditional filtration equipment, the horizontal vacuum belt filter features a compact design structure with a small footprint and flexible layout. This is a significant advantage for enterprises with limited space, enabling efficient production operations within confined spaces.

Hesheng Filter

Hesheng Filter

Call us on:

Call us on:  Email Us:

Email Us:  No.255 Shenzhen North Road, Laixi City, Qingdao City, Shandong P.R, China

No.255 Shenzhen North Road, Laixi City, Qingdao City, Shandong P.R, China