Chemical filtration is a critical process in both aquatic environments and industrial operations, designed to remove contaminants and purify liquids. While chemical filtration is often discussed in the context of aquariums, it plays a significant role in various industrial applications. This article will explore the definition and examples of chemical filters, delve into their applications in aquariums, and highlight industrial uses and processes. We will also provide selection tips for choosing the right filters, whether you are interested in an industrial filtration system or a simple aquarium filter, ensuring optimized performance and efficiency.

Definition of Chemical Filtration

Chemical filtration involves the removal of impurities from liquids via chemical reactions or adsorption processes. The filters used in chemical filtration, such as activated carbon, are engineered to attract specific pollutants, thus purifying the substance being treated. In industrial filter manufacturing, materials like activated carbon can effectively remove organic compounds, chloramines, and various pollutants, enhancing the purity and functionality of the liquids processed.

Examples of Chemical Filters

Chemical filters come in various forms, each suited to specific applications. Common examples include activated carbon filters, resin filters, and synthetic polymer filters. The choice of filter material can significantly impact the efficiency of the filtration process in industries and aquariums alike.

Filter Type | Material | Use Case |

Activated Carbon | Charcoal, Coconut Shell | Organic pollutant removal, taste and odor control |

Resin Filter | Ion-Exchange Resin | Water softening, demineralization |

Synthetic Polymer | Nylon, Polyester | Particulate removal, chemical resistance |

Applications in Aquariums

Chemical filters are integral to maintaining healthy aquatic environments. In aquariums, these filters help remove toxins like ammonia and nitrates, ensuring water clarity and the well-being of aquatic life. Activated carbon and resin filters are commonly used in aquarium setups due to their effectiveness in chemical filtration processes.

Industrial Uses and Processes

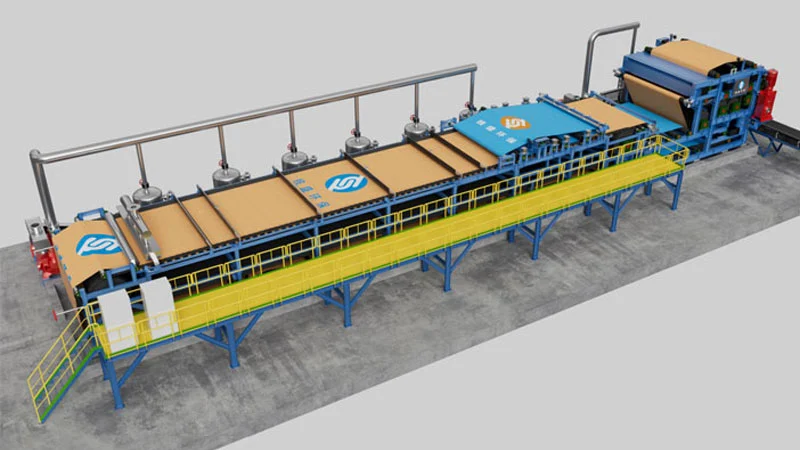

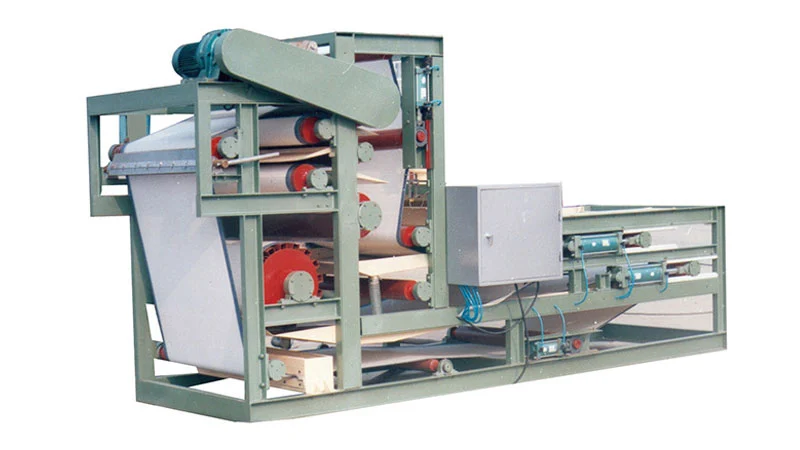

In industries, chemical filtration is key for handling processes such as waste management, chemical purification, and liquid preparation. Equipment like belt filter presses and filter press machines utilize chemical filters to enhance filtration efficiency and throughput. For instance, belt presses are employed in water treatment facilities and chemical plants owing to their reliable filter press operation.

Selection Tips for Filters

Choosing the right filter requires an understanding of your specific needs, whether for aquariums or industrial applications. Consider factors such as the type of chemicals being filtered, desired purity levels, and equipment compatibility. Reputable industrial filter manufacturers, such as Industrial Filter Manufacturers Inc, provide guidance and solutions tailored to various filtration needs. Their expertise extends to custom filter designs, ensuring optimal filtration performance.

For aquarium enthusiasts, selecting filters involves considering factors such as tank size, fish species, and water quality. Brands specializing in aquarium filters offer a range of options suited to different aquatic ecosystems.

Conclusion

Chemical filtration is pivotal in both aquariums and industrial applications, offering solutions that ensure purity and safety. Whether you are dealing with complex industrial processes or maintaining a vibrant aquatic ecosystem, understanding the nuances of chemical filtration is essential. The selection of the right filters, informed by expertise and customization, can significantly impact the success of your filtration system. For further insights, consult reputable industrial filter manufacturers or aquarium specialists, ensuring that your filter machine or filter tube serves your needs effectively.

Hesheng Filter

Hesheng Filter