Industrial filtration systems play a pivotal role in ensuring the efficiency and reliability of numerous industrial processes. Among the prominent industrial filter manufacturers is Hesheng Filters, renowned for their robust and high-performing chemical filtration products. Understanding the lifespan of Hesheng Filters involves analyzing several factors including usage environment, maintenance practices, and product specifications. This article explores these key elements, providing insights into how you can maximize the productivity of your filtration systems and make informed decisions when selecting and maintaining these vital tools.

Factors Affecting Longevity

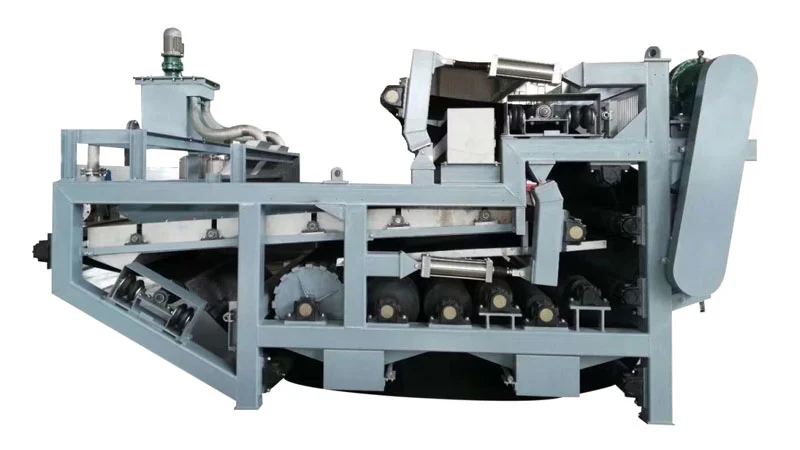

The durability of Hesheng Filters is influenced by various factors, including the quality of materials used and the operational conditions they endure. High-quality materials ensure that filters withstand the rigorous demands of industrial environments, particularly in settings where filter press operation is frequent.

Factor | Impact on Longevity | Example |

Material Quality | High durability, resistance to chemicals | Filter cloth with enhanced tensile strength |

Usage Environment | Corrosion resistance, temperature tolerance | Filters used in high-temperature chemical plants |

Maintenance Practices | Regular upkeep extends life | Scheduled cleaning of belt filter press |

Operational Load | Overuse decreases lifespan | Frequent operation of belt press |

Replacement Schedules

Determining an optimal replacement schedule is vital for achieving peak performance with Hesheng Filters. It's crucial to balance efficiency with cost, ensuring that filters are replaced before they lose effectiveness but not so frequently that costs become excessive.

Typically, industrial filter manufacturers like Hesheng recommend evaluating the filter's performance at regular intervals. Factors influencing replacement include the number of operational hours, the types of materials filtered, and signs of wear and tear. Documenting this data can inform decisions and prevent unnecessary downtime caused by filter machine failures.

Performance Monitoring

Regular performance monitoring is essential for maintaining the effectiveness of filter tube systems. This involves checking for clogging, tracking flow rates, and ensuring seal integrity is maintained throughout the operation.

Monitoring tools, including pressure gauges and flow meters, can be integrated into filter press machines to provide real-time feedback. This data helps operators to anticipate maintenance needs and intervene before major breakdowns occur. Keeping detailed logs also supports predictive maintenance strategies that can extend the life of the filtration system significantly.

Extending Life Tips

For those looking to prolong the life of their filter press systems, attentive care and strategic use are key. Here are several actionable insights:

Invest in high-quality filter cloth and materials to withstand harsh conditions.

Conduct regular inspections and cleanings to prevent buildup that can damage the filter machine.

Ensure proper training for operators on how to handle and maintain belt filter systems effectively.

Implement advanced monitoring technology to preemptively address issues before they escalate.

Consider custom-made solutions to fit specific operational needs, which can enhance system adaptability and longevity.

Warranty Info

Purchasing industrial filtration systems with robust warranties can also provide peace of mind. Hesheng Filters, known for their reliability and performance, offer comprehensive warranties that cover certain replacement and repair costs.

It's advisable to thoroughly review warranty terms, particularly noting the coverage provided for regular wear and tear versus damage caused by excessive strain or improper usage. Understanding these details ensures you can maximize your investment and maintain high operational standards without incurring unplanned expenses.

In conclusion, the lifespan of Hesheng Filters is affected by many factors, all of which can be managed through attentive practices and informed choices. By leveraging expert knowledge and strategically managing your industrial filtration resources, you not only optimize operational efficiency but also extend the durability of your chemical filter systems significantly, ensuring seamless operations across various applications.

Hesheng Filter

Hesheng Filter