In many industries, efficient dewatering processes are essential for wastewater treatment and material handling. Belt filter presses have emerged as a pivotal technology in these applications due to their effectiveness in reducing moisture content in sludge and other materials. This article explores how belt filter presses function, their components, advantages over other methods, operational dynamics, and their common industrial applications. By the end of this guide, you will understand why they are a preferred choice for industrial filtration systems and how leading industrial filter manufacturers have innovated them to meet diverse demands.

Working Principle of Belt Presses

The belt filter press is mechanical devices that dewater sludge through a combination of gravity drainage and mechanical pressure. This section unpacks the operating principle that makes these machines efficient:

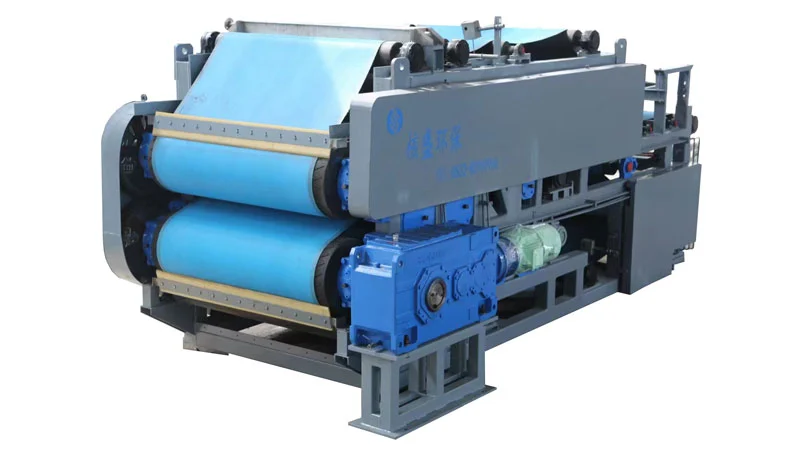

Gravity Zone: The dewatering process begins as the sludge is fed onto a moving belt where gravity allows the initial phase of water separation. The use of a filter cloth in this stage facilitates the drainage.

Wedge Zone: In this phase, the sludge starts to thicken, and mild pressure is applied to further reduce the liquid content.

Pressurization Zone: This final phase involves multiple rollers that compress the sludge with increasing pressure, thereby extracting maximum water content, leaving a concentrated solid cake.

The intrinsic design and function of belt filter presses rely heavily on the selection of materials and design of each component to ensure durability and efficiency. Understanding these elements provides insights into why they are favored by industrial filter manufacturers.

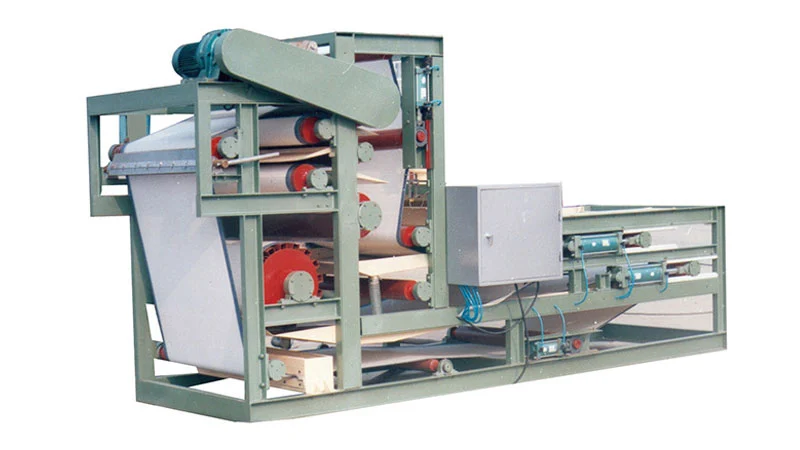

Components of a Belt Filter Press

The performance of a belt press largely depends on the quality and design of its components. Here is a detailed look at what constitutes a standard belt filter press:

Component | Material | Function |

Filter Cloth | Polyester, Polypropylene | Facilitates separation of solids from liquids |

Rollers | Stainless Steel | Applies mechanical pressure for dewatering |

Drive System | Electric Motor, Gearboxes | Ensures consistent operation of belts |

Belt | Rubber, Fabric Reinforced | Supports sludge and maintains structure under pressure |

Each component is selected for its ability to withstand the operational demands, ensuring long-term performance and minimal maintenance. The materials used in these components signify the high standards maintained by industrial filter manufacturers inc.

Advantages Over Other Methods

When compared to other dewatering technologies, belt filter presses present several distinct advantages:

Efficiency: They achieve significant moisture reduction, which decreases sludge volume and weight, hence reducing disposal costs.

Continuous Operation: Unlike batch filter press operations, belt presses offer continuous dewatering, enhancing productivity.

Flexibility: These systems can handle a wide range of sludge types and concentrations.

Minimized Chemical Usage: With better mechanical separation, the reliance on chemical filtration can be reduced.

These advantages make belt filter presses a compelling choice across various industries that require efficient and cost-effective dewatering solutions. Their superiority in performance and utility is a testament to the dedication of industrial filter manufacturers to innovation and excellence.

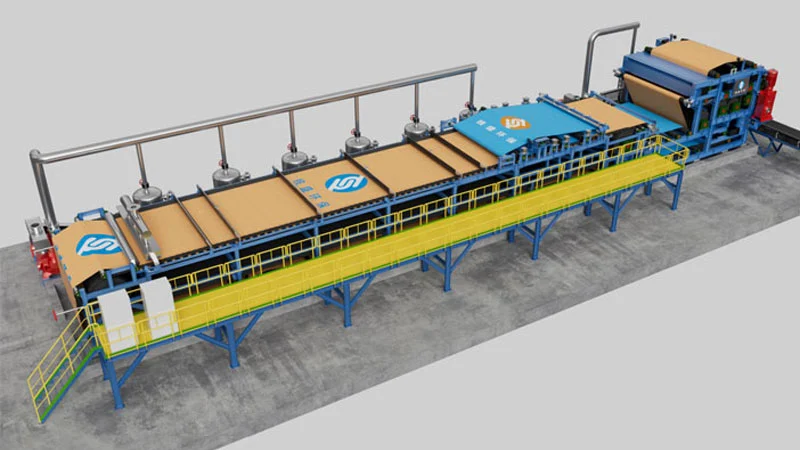

Typical Belt Speeds and Operations

The operation of a belt filter press involves adjusting various parameters to optimize performance, including belt speeds, which are crucial for efficient dewatering. Here's a breakdown of how these speeds influence operations:

Parameter | Typical Range | Impact |

Belt Speed | 1.5 to 10 meters/minute | Higher speeds reduce processing time but may affect dewatering quality |

Pressure | Up to 20 psi | Ensures effective water removal at different sludge consistencies |

Sludge Feed Rate | Up to 500 kg/hour | Influences time and depth of processing of sludge |

Understanding these parameters and their adjustments can lead to maximizing the output of belt filter presses. Fine-tuning these values allows industrial filter manufacturers to offer tailored solutions to meet specific operational needs.

Common Industrial Uses

Belt filter presses serve a wide array of industries, primarily because of their adaptability in managing different types of sludge. Here are some common areas where these machines are integral:

Wastewater Treatment Plants: Essential for reducing moisture content before sludge is sent to disposal sites or further treatment processes.

Food and Beverage Industry: Used in managing waste products and by-products.

Mining and Mineral Processing: Critical in processing slurry and tailings to enhance material recovery.

Chemical Processing: Helps manage waste and recover chemicals, aided by chemical filtration methods.

The role of a filter press machine in these industries cannot be overstated, as it not only aids in material efficiency but also contributes significantly to environmental management efforts.

Conclusion

Understanding the working and advantages of belt filter presses gives us insights into why they are invaluable in modern industrial processes. These machines not only make operations more efficient but also promote sustainable practices by reducing waste and optimizing resource use. The commitment of industrial filter manufacturers to improving these technologies ensures continuous advancements that cater to evolving industry needs. For anyone exploring solutions in chemical filtration, dewatering, or general filter press operation, belt filter presses are indeed an exemplary choice that promises performance and reliability.

Hesheng Filter

Hesheng Filter