In industries where solid-liquid separation is a critical step — such as mining, chemical processing, metallurgy, and FGD desulfurization — choosing the right filtration technology can significantly impact efficiency, cost, and environmental compliance. Among the many options available, the horizontal belt vacuum filter (HBVF) stands out as one of the most reliable and efficient choices.

In this article, we'll explore the top 5 benefits of using a horizontal belt vacuum filter for industrial applications, based on both field-tested performance and the expertise of Hesheng, a leading filtration equipment manufacturer with over 30 years of industry experience.

What is a Horizontal Belt Vacuum Filter?

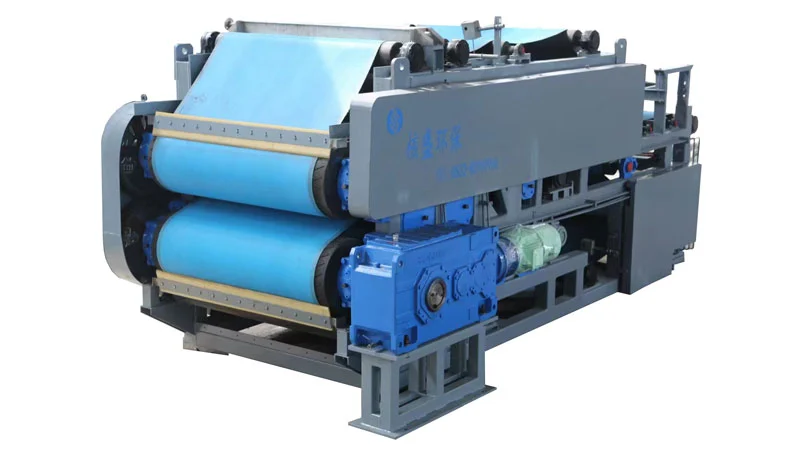

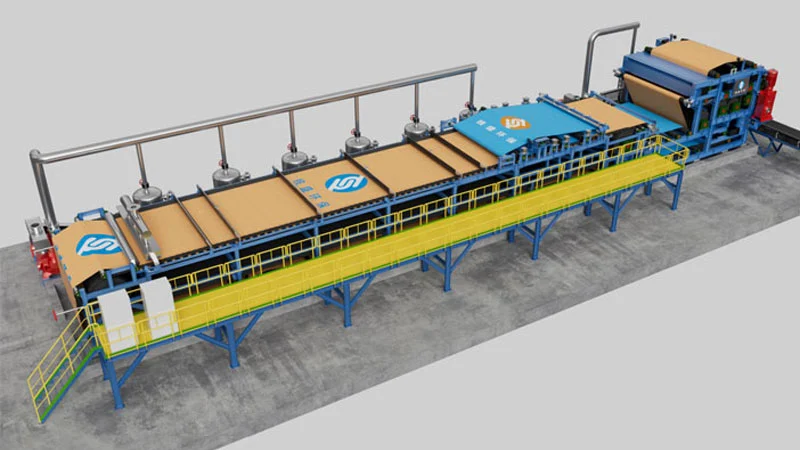

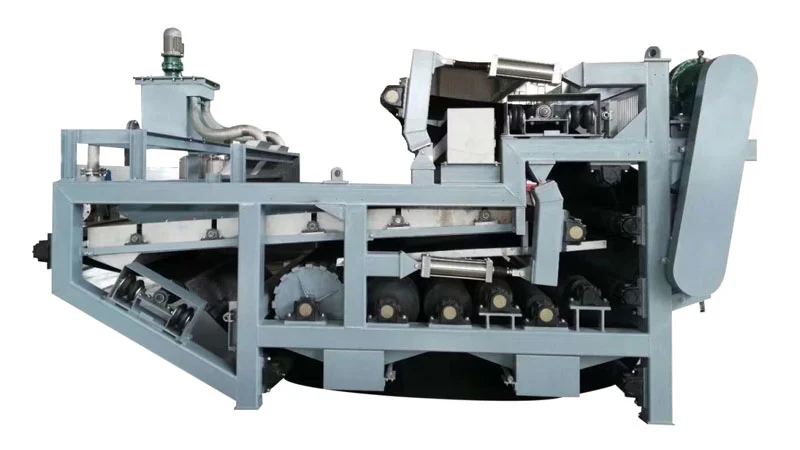

A horizontal belt vacuum filter is a continuous filtration system designed to separate solids from liquids in industrial slurries. It operates using a fixed vacuum chamber, a continuous rubber belt, and high-efficiency filter cloth. Slurry is fed onto the belt, and as it moves through vacuum zones, liquid is pulled through the cloth, leaving behind a dewatered solid cake. The process includes automated stages for filtration, washing, and drying, making it ideal for industries requiring high throughput and low moisture content.

Hesheng's DU horizontal vacuum belt filter is engineered for demanding applications, offering optimal dewatering, reduced moisture content, and enhanced process stability. Hesheng delivers customized solutions backed by rigorous quality control and expert after-sales service.

Top 5 Benefits of Horizontal Belt Vacuum Filters

1. Continuous and Fully Automated Operation

Horizontal belt vacuum filters operate continuously, integrating feeding, filtration, washing, drying, and discharge into a seamless process. This automation minimizes manual intervention, reducing labor costs and downtime. According to industry sources,

Hesheng's Advantage: The DU filter's fully automated system streamlines operations, allowing operators to focus on other tasks. Its design ensures minimal idle time, boosting overall efficiency.

Real-World Impact: In a case study, Hesheng delivered a DU filter for silicon slag treatment, achieving high automation and significantly reducing labor intensity for the client.

2. Superior Filtration Performance

HBVFs excel in producing uniform cake formation and thorough washing, which enhances product purity and reduces residual moisture. This is particularly valuable in applications requiring high-purity outputs, such as pharmaceuticals or chemical intermediates. The ability to perform multiple-stage washing, as noted by Micronics, allows for the removal of fine particles, improving product quality.

Hesheng's Advantage: The DU filter is optimized for challenging materials like FGD gypsum, mining tailings, and chemical residues. Its high-efficiency filter cloth ensures consistent cake formation and effective washing.

Real-World Impact: In the rare earth carbonate industry, Hesheng's DU filter provided high-precision filtration with a fully enclosed design, meeting stringent safety and quality standards.

3. Energy Efficiency

Energy efficiency is a key concern in industrial operations, and HBVFs address this with stable vacuum performance that minimizes power consumption while maintaining high throughput. ANDRITZ highlights that their HBVFs are designed to keep operating costs low, a feature shared by Hesheng's DU model.

Hesheng's Advantage: The DU filter's optimized vacuum system ensures energy-efficient operation, aligning with sustainability goals and reducing operational costs.

4. Modular Design Enables Multi-Step Filtration

Another key benefit is the modular layout of HBVFs, which allows different zones for:

Filtration

Cake washing

Cake drying

Discharge

This zoned approach means you can customize each step of the process depending on your slurry’s characteristics and product quality requirements.

Typical Enhancements:

Improve product purity with multiple washing stages.

Reduce residual moisture with extended drying zones.

Customize belt speed and vacuum pressure per zone.

5. Lower Operational & Maintenance Costs

HBVFs are designed for long-term, low-cost operation:

Reduced need for manual labor (compared to filter presses).

Fewer moving parts = lower maintenance costs.

Energy-efficient vacuum system.

At Qingdao Hesheng, we've helped customers lower the total cost of ownership by replacing outdated filtration systems with our DU vacuum belt filter, resulting in higher productivity and reduced operating expenses.

Why Choose Hesheng Horizontal Vacuum Belt Filters?

As a high-tech enterprise specializing in intelligent filtration systems, Qingdao Hesheng Intelligent Environmental Protection Equipment Co., Ltd. brings you:

Over 30 years of filtration industry experience

Advanced production and R&D capabilities

In-house testing with customer samples

Customized design and engineering

Full lifecycle support from manufacturing to after-sales service

FAQs About Horizontal Belt Vacuum Filters

Q1: How does a horizontal belt vacuum filter work?

A: Slurry is distributed onto a moving filter cloth. Vacuum pressure pulls the liquid through the cloth, forming a cake, which then undergoes optional washing, drying, and automatic discharge.

Q2: What materials can be filtered with HBVFs?

A: HBVFs are ideal for fine particles and sticky slurries such as gypsum, silicon slag, coal slurry, and rare earth materials.

Q3: How do HBVFs compare with filter presses?

A: HBVFs offer continuous operation, lower labor requirements, and higher processing volumes, making them better suited for industrial-scale production.

Q4: How does it compare to other filtration methods?

Compared to rotary drum or disc filters, HBVFs offer better visibility, reduced slurry inventory, and superior cake washing. They are ideal for low-moisture applications and multi-stage washing, as noted by Micronics.

Hesheng Filter

Hesheng Filter