When it comes to solid-liquid separation in industries like mining, chemicals, metallurgy, and power plants, the horizontal belt vacuum filter (HBVF) remains one of the most trusted and efficient technologies. However, many engineers, plant managers, and procurement professionals often have similar questions when considering this type of filtration equipment.

In this article, we answer the Top 10 most commonly asked questions about horizontal belt vacuum filters to help you make informed decisions for your operations.

1. What is a Horizontal Belt Vacuum Filter?

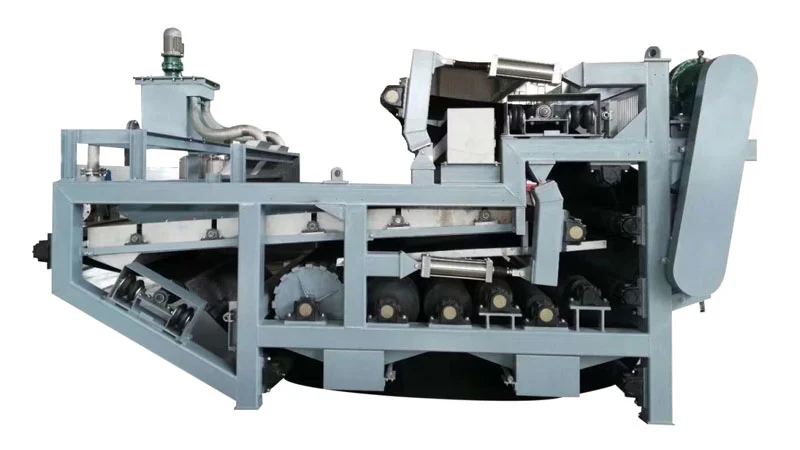

A horizontal belt vacuum filter is a continuous filtration system that uses vacuum suction to separate solids from liquids in industrial slurries, producing a low-moisture solid cake. It is ideal for applications requiring high-purity outputs and efficient dewatering. Hesheng's DU model is distinguished by its modular design, which facilitates easy transportation and assembly, and its ability to perform continuous processes, including feeding, filtering, washing, drying, and cloth washing. The DU filter supports unmanned operations with remote and local control, reducing labor costs and enhancing efficiency. Its robust construction and high-pressure cloth washing system further extend the lifespan of the filter cloth and rubber belt.

Key Features of Hesheng's DU Model:

Modular design for flexible assembly

Automated processes for high efficiency

Remote control for unmanned operation

High-pressure cloth washing for extended lifespan

2. How Does a Horizontal Belt Vacuum Filter Work, and What Makes It Efficient?

Hesheng’s HBVFs operate by feeding slurry onto a continuous filter cloth supported by a rubber drainage belt. A vacuum system draws liquid through the cloth, forming a solid cake, which is then washed and dried in automated stages. The filter's efficiency is enhanced by features such as:

Friction Reduction: Rollers, air cushions, and multiple friction belts reduce wear on the rubber belt, prolonging its life.

High-Pressure Cloth Washing: Uses high-pressure water to clean the filter cloth, improving regenerative effects and extending cloth lifespan.

Sectional Filtrate Collection: Allows separate collection of mother liquor and wash liquor, improving process control.

Energy Efficiency: Stable vacuum performance minimizes energy consumption while maintaining high throughput.

These features ensure consistent performance, low moisture content in the cake, and reduced operational costs.

3. What Are the Key Components of Horizontal Belt Vacuum Filter?

Hesheng's HBVFs consist of several critical components that work together to ensure high performance:

Filter Cloth and Rubber Drainage Belt: Move synchronously to ensure uniform filtration and cake formation.

Vacuum System: Provides consistent suction for efficient liquid removal, reducing moisture content in the cake.

Washing System: Uses high-pressure water or filtrate for thorough cake washing and cloth cleaning, enhancing product purity.

Control System: PLC-based, enabling remote monitoring and unmanned operation for precise process control.

Support Deck: Includes rollers, air cushions, or pallets to reduce friction and extend belt life.

These components are designed for durability and efficiency, minimizing maintenance needs and ensuring reliable operation in demanding environments.

Component | Function | Hesheng's Advantage |

Filter Cloth | Separates solids from liquids | High-efficiency cloth with extended lifespan |

Rubber Drainage Belt | Supports filter cloth, facilitates liquid flow | Friction-reducing design for durability |

Vacuum System | Draws liquid through cloth | Stable performance for energy efficiency |

Washing System | Cleans cake and cloth | High-pressure washing for regenerative effects |

Control System | Manages operation and automation | PLC-based for remote and unmanned operation |

4. What Are the Advantages of a Horizontal Belt Vacuum Filter?

Continuous operation — ideal for 24/7 industrial use

Efficient solid-liquid separation for fine or viscous slurries

Lower labor & maintenance costs compared to filter presses

Customizable zones (washing, drying)

Energy-efficient vacuum system

5. How Is It Different from a Filter Press?

Aspect | Horizontal Belt Vacuum Filter | Filter Press |

Operation Mode | Continuous | Batch |

Labor Intensity | Low | High |

Maintenance | Lower | Moderate to high |

Throughput | High | Medium |

Application | Large-scale, continuous | Smaller-scale, varied |

Key Benefit: HBVF offers better efficiency and scalability for continuous production lines.

6. What Types of Materials Can Be Processed?

HBVFs handle a wide range of materials, including:

Gypsum slurry (FGD)

Coal slurry

Tailings

Rare earth carbonate

Silicon slag

Chemical suspensions

Metallurgical wastewater

7. How Do I Choose the Right Model for My Application?

Consider these factors:

Slurry characteristics (particle size, viscosity, solid content)

Required moisture content of filter cake

Throughput / production volume

Available space

Energy efficiency goals

At Qingdao Hesheng, we offer customized testing based on your samples to recommend the best model.

8. How Can I Improve Filtration Efficiency?

Tips for maximizing performance:

Optimize vacuum pressure settings

Ensure proper slurry distribution

Regularly clean and maintain the filter cloth

Adjust belt speed to match slurry properties

Utilize multi-stage washing if necessary

9. How to Maintain a Horizontal Belt Vacuum Filter?

Routine Maintenance Includes:

Inspecting and replacing the filter cloth

Checking vacuum pump performance

Cleaning pipelines and discharge systems

Ensuring belt alignment and tension

Monitoring for leaks or wear in seals

Proper maintenance extends equipment lifespan and ensures consistent performance.

10. Why Should I Choose Hesheng's Horizontal Belt Vacuum Filter Over Other Brands?

Hesheng stands out due to:

30+ Years of Experience: A team of top filtration experts with extensive industry knowledge.

Innovative Technology: Energy-efficient, low-maintenance, and customizable filters tailored to client needs.

Proven Success: Real-world applications in rare earth, silicon slag, and FGD industries demonstrate reliability.

Comprehensive Support: From dewatering tests to after-sales service, Hesheng ensures customer satisfaction.

Hesheng's commitment to quality, innovation, and customer-centric solutions makes them a trusted partner for industrial filtration needs.

About Hesheng

Qingdao Hesheng Intelligent Environmental Protection Equipment Co., Ltd. is a high-tech enterprise specializing in the production, R&D, and sales of intelligent filtration equipment. With over 30 years of experience, Hesheng has assembled top talent in the Chinese filtration field, supported by advanced machining equipment, professional production lines, and a rigorous quality control system. Their product portfolio includes horizontal vacuum belt filters, ceramic disc filters, stacked filter presses, and more, serving global industries with a commitment to innovation and excellence.

Case Studies

Hesheng's HBVFs are widely used in industries such as:

Mining: Dewatering tailings and concentrates.

Metallurgy: Separating metal residues.

Chemical Processing: Handling chemical intermediates and residues.

Flue Gas Desulfurization (FGD): Dehydrating gypsum.

Pharmaceuticals: Producing high-purity intermediates.

Food Processing: Clarifying liquids and recovering solids.

Case Studies:

Rare Earth Carbonate Industry: Hesheng delivered a customized DU horizontal vacuum belt filter to a leading listed company in the rare earth sector. The filter featured a fully enclosed sliding window design for gas isolation and operational safety. It achieved high-precision filtration tailored to rare earth production needs and integrated remote central control systems for intelligent, automated operation. This project enhanced process safety and efficiency, earning Hesheng recognition as a trusted environmental protection partner.

Silicon Slag Treatment: Hesheng's DU filter achieved breakthroughs in filtering silicon slag, a challenging material for solid-liquid separation. The filter's high automation reduced labor intensity, while its large capacity lowered operational costs. It replaced less efficient traditional methods, improving separation efficiency and reducing investment costs. Clients reported significant cost savings and high satisfaction with performance.

These examples highlight Hesheng's ability to deliver tailored, high-performance filtration solutions.

Hesheng's DU horizontal belt vacuum filters offer unmatched performance, reliability, and customization for industrial solid-liquid separation. Their advanced features, such as high automation, energy efficiency, and robust designs, make them ideal for industries like mining, chemical processing, and FGD. Backed by over 30 years of expertise and comprehensive support, Hesheng is the go-to choice for businesses seeking efficient filtration solutions.

Hesheng Filter

Hesheng Filter