Differences between Filtration Media and Core Structure

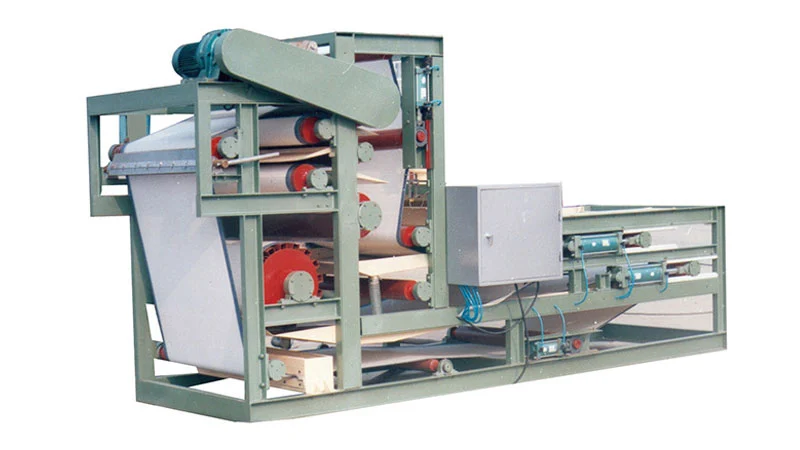

The rotary vacuum disc filter uses traditional filter cloth as the filtration medium. This equipment is composed of multiple metal frame discs, with part of the disc submerged in the slurry. It relies on vacuum suction to draw out the liquid, forming a filter cake. The filter cloth needs to be replaced periodically, requiring relatively frequent maintenance.

The ceramic vacuum disc filter uses inorganic porous ceramic plates as the filtration medium. These plates have advantages such as high strength, corrosion resistance, and long lifespan. The ceramic plates can be repeatedly cleaned and regenerated, are not easily clogged, and are particularly suitable for fine materials and corrosive liquids.

Comparison of Filtration Efficiency and Filtrate Quality

In terms of filtration precision, the ceramic vacuum disc filter has a higher advantage. Its microporous ceramic can produce a filter cake with a lower moisture content and the filtrate is clearer, making it ideal for the dehydration process of mineral concentrates with strict product quality requirements.

In contrast, the rotary vacuum disc filter has a faster filtration speed and is suitable for large-scale processing scenarios with medium to low precision requirements. It can achieve stable operation at a lower cost. However, the moisture content of the filter cake is relatively high, requiring subsequent drying equipment.

Energy Consumption, Operating Costs, and Automation Level

Thanks to the high water permeability of the ceramic plates and the energy-saving pump system, the ceramic vacuum disc filter has low operational energy consumption and is easy to integrate with an automated control system. The frequency of maintenance is also significantly reduced, making it suitable for long-term stable operation.

In comparison, although the initial investment for a rotary vacuum disc filter is relatively low, the filter cloth is easily worn and needs to be replaced regularly. The long-term maintenance costs are relatively high, and it relies more on the operators.

Applicable Industries and Material Comparison

The ceramic vacuum disc filter is widely used in high-precision filtration scenarios such as mining, metallurgy, and coal chemical industries. It is especially suitable for the dehydration of fine mineral concentrates like copper, iron, and zinc.

The rotary vacuum disc filter, on the other hand, performs well in industries such as paper making, light chemical industry, and municipal sludge dewatering. It is suitable for material systems with higher concentrations and faster filtration speed requirements.

Conclusion

Overall, the ceramic vacuum disc filter is favored by high-end industries for its high filtration precision, low energy consumption, and long lifespan. The rotary vacuum disc filter is suitable for medium to low-end, high-volume applications due to its simple structure and large processing capacity. Users should make a scientific selection based on actual working conditions, material characteristics, and budget to maximize the value of the equipment.

Hesheng Filter

Hesheng Filter