Negative pressure filter equipment refers to specialized machinery that uses vacuum (pressure below atmospheric) to separate solids from liquids. This equipment can integrate automatic cycles—filtration, cake washing, cake discharge, and filter cloth cleaning. It is valued for its high filtration efficiency, large production capacity, good washing performance, low cake moisture content, operational flexibility, and ease of maintenance.

Operating Principles and Mechanisms

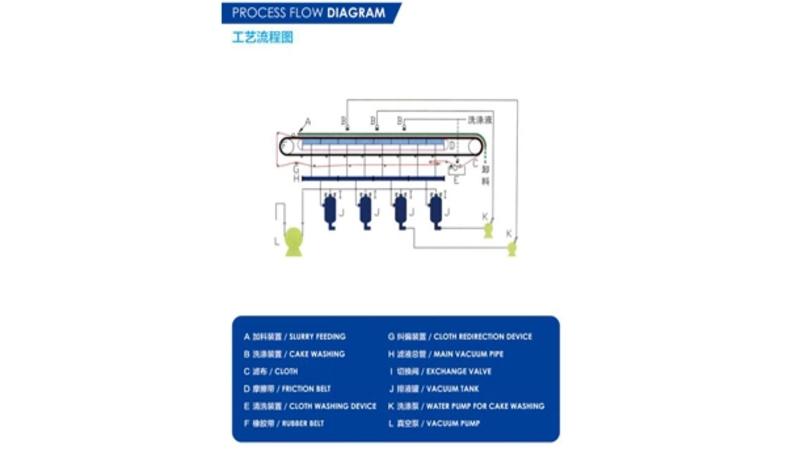

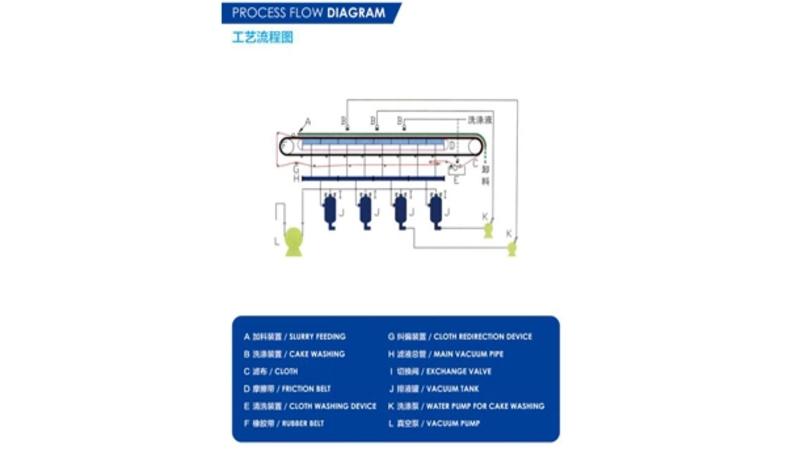

The core principle of negative pressure filter equipment is creating a vacuum to draw liquid through a filter medium while retaining solids. For example:

In a ceramic disc configuration, a vacuum creates a negative-pressure region on the disc's surface. Solids form a cake while filtrate passes through, and cake removal is achieved via back-blowing or scraping.

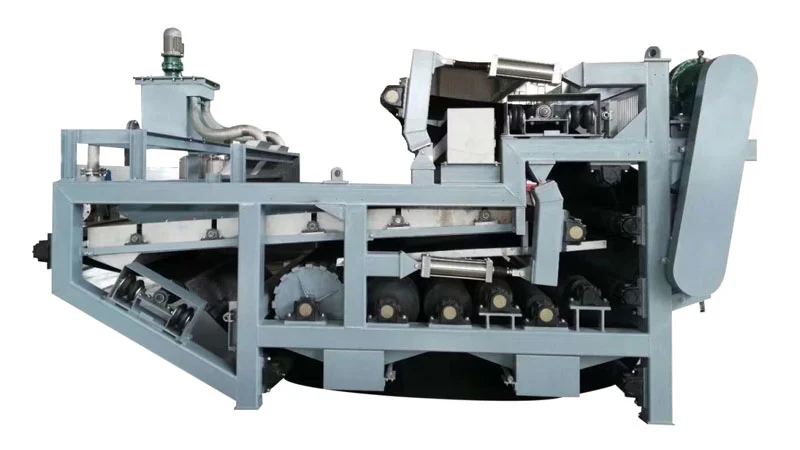

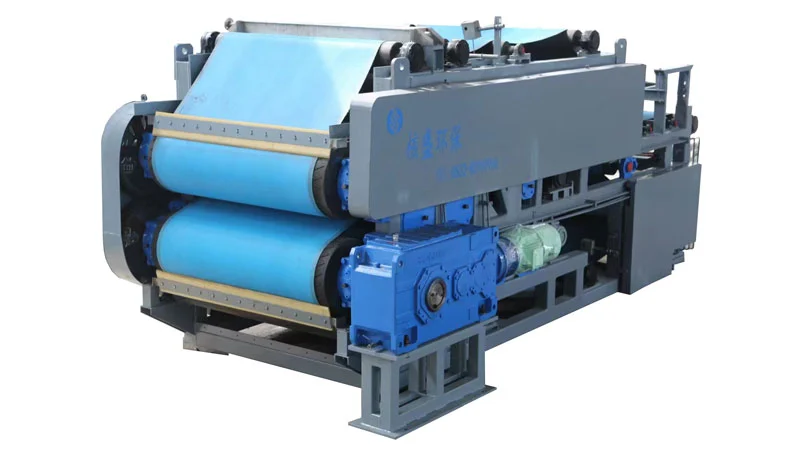

In belt filter systems, filtering fabric serves as the medium, where gravity and vacuum work together to separate solids and liquids. Filtration, washing, dewatering, and discharge occur in a continuous operation.

Industrial Applications and Advantages

Negative pressure filter equipment is widely used in metallurgy, mining, petrochemicals, coal washing, paper, fertilizer, food, pharmaceuticals, environmental protection, flue gas desulfurization gypsum dehydration, tailings handling, and more.

Key advantages include:

Fully automated operation covering feeding, filtration, washing, drying, and cake discharge, reducing manual labor.

High filtration and washing efficiency, producing low-moisture cakes and high throughput.

Compact design saves floor space and allows continuous, stable, and energy-efficient operation.

Simple maintenance with customizable options for diverse slurry types, minimizing downtime and costs.

Selection Criteria and Performance Comparison

Selecting the right negative pressure filter equipment depends on slurry concentration, desired throughput, cake dryness, washing requirements, maintenance capacity, and available space.

| Equipment Type | Advantages | Best Suited For |

|---|

| Belt Filter | Continuous operation, integrated washing/discharge | High-volume slurries requiring continuous filtering |

| Ceramic Disc Filter | Compact footprint, efficient vacuum usage | Space-limited plants, high-concentration slurries |

| Rotary Vacuum Disc Filter | Large filtration area, efficient energy use | Industrial-scale dewatering processes |

The belt filter supports automatic cycles of feeding, filtration, washing, drying, and discharge, ideal for continuous operation.

The ceramic disc filter uses capillarity under vacuum to efficiently separate solids and liquids, with cleaning systems to maintain performance.

Rotary vacuum disc filters operate with rotating discs partially immersed in slurry, drawing liquid through the disc while scraping off solid cake. They are compact and efficient for high-concentration, large-scale applications.

In conclusion, negative pressure filter equipment provides a versatile and efficient solution for industrial solid–liquid separation. Different types—belt, ceramic disc, and rotary vacuum disc—offer advantages in capacity, moisture control, energy efficiency, and automation. Choosing the right equipment ensures optimal performance tailored to specific operational needs.

Hesheng Filter

Hesheng Filter