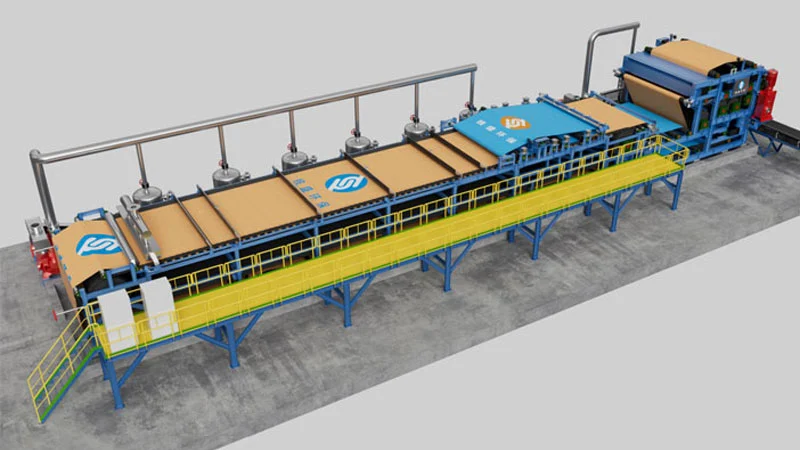

In modern industry, solid-liquid separation technology has become a crucial part of many production processes. The rotary vacuum disc filter, as a highly efficient and continuously operating filtration device, is widely used in metallurgy, mining, chemical industry, papermaking, and environmental protection due to its advantages such as energy saving, large processing capacity, and strong adaptability. This article will provide a detailed analysis of the technical characteristics and development prospects of this equipment from aspects such as working principle, equipment structure, and application value.

Brief Introduction to the Working Principle

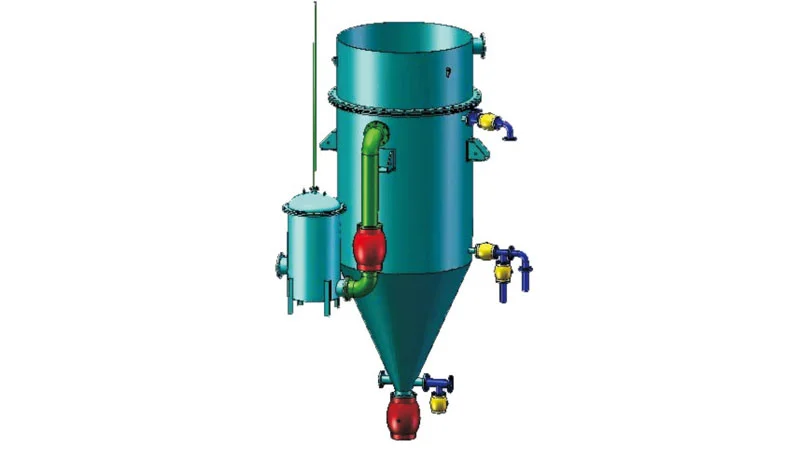

The rotary vacuum disc filter mainly consists of several discs with filter cloths, which are partially immersed in the suspension and rotate around a horizontal axis. Under the action of the vacuum system, a negative pressure region is formed on the outer surface of the filter cloth on the disc. The solid particles in the slurry are adsorbed on the surface of the filter cloth to form a filter cake, while the liquid passes through the filter cloth into the central pipe and is discharged. As the disc rotates to the discharge area, the filter cake is removed by backblowing or scraper, thus achieving continuous filtration.

Outstanding Structural Advantages

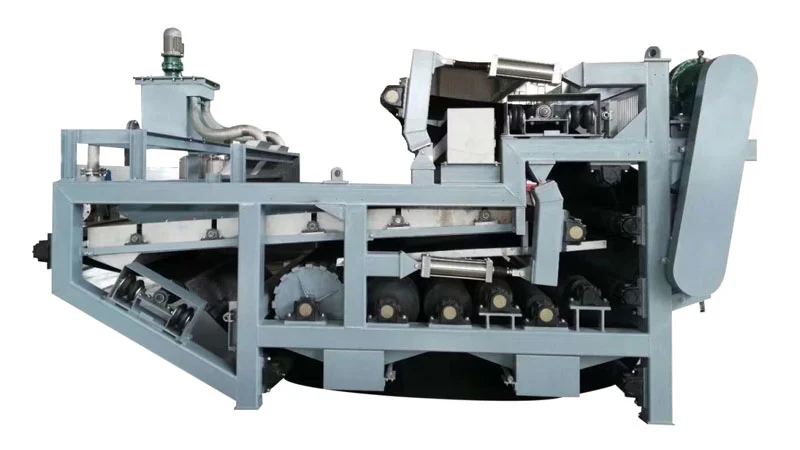

Compared with traditional filtration equipment, the rotary vacuum disc filter has multiple structural advantages:

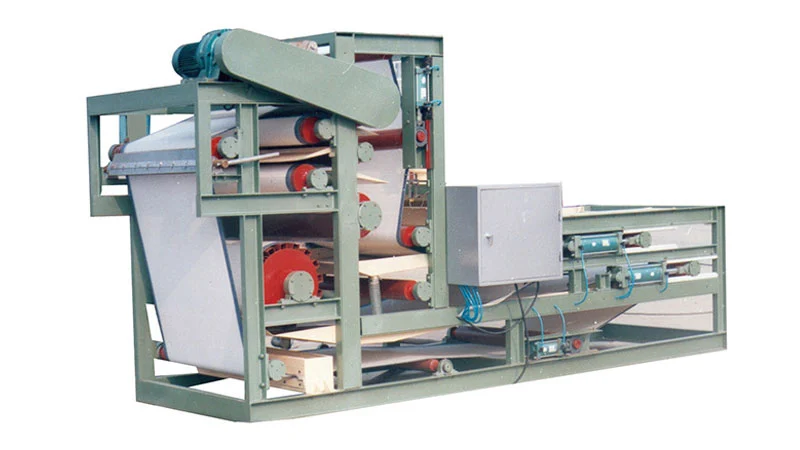

Compact structure, small footprint: The disc structure is vertically arranged, saving plant space;

Strong processing capacity: Suitable for high-concentration slurry, with a large filtration area;

Continuous and stable operation: Simple mechanical transmission structure, easy to maintain;

Low energy consumption, high efficiency: The vacuum system can be recycled, reducing operating costs;

Strong adaptability: The filter cloth, filter disc material, and slag discharge method can be selected according to different material characteristics.

Wide Application Fields

The rotary vacuum disc filter performs well in many industries:

Metallurgical mining: Used for dewatering iron ore, copper ore, and gold ore concentrates;

Chemical industry: Suitable for solid-liquid separation of inorganic salts, dyes, pigments, and other products;

Papermaking industry: Widely used in white water recovery and pulp concentration;

Environmental engineering: Treats municipal sludge and solid residues in industrial wastewater.

Reliable, Efficient, and Green Filtration Solution

In conclusion, the rotary vacuum disc filter is an indispensable solid-liquid separation device in modern industrial fields. With its high efficiency, low energy consumption, and strong adaptability, it brings higher production efficiency and lower operating costs to enterprises. With the tightening of environmental policies and the acceleration of industrial upgrading, this equipment will play a greater value in more critical scenarios.

Hesheng Filter

Hesheng Filter