In wastewater treatment and industrial sludge management, dewatering is a critical process for minimizing waste volume and reducing disposal costs. One of the most widely used and cost-effective dewatering technologies is the belt filter press (BFP). At Hesheng Filter, we specialize in delivering high-efficiency belt press for sludge dewatering systems engineered to meet the evolving needs of global industries.

What Is a Belt Filter Press?

A belt filter press is a continuous mechanical dewatering device designed to remove water from sludge through a series of gravity drainage and pressure filtration steps. This method is especially effective for treating municipal and industrial sludges with moderate-to-high water content.

How Does a Belt Filter Press Work?

The operation of a belt press typically includes several sequential zones:

1. Sludge Conditioning

Polymers are added to the sludge to promote flocculation—this encourages fine particles to bind together into larger flocs, enhancing separation efficiency.

2. Gravity Drainage Zone

The flocculated sludge is applied to a moving belt. Free water drains away by gravity through the porous belt material.

3. Wedge/Low-Pressure Zone

The sludge passes through a narrowing path where two belts compress it gently, removing more water without disturbing the flocs.

4. High-Pressure Zone

The material is squeezed between rollers under increasing pressure, significantly reducing the water content and forming a compact, dry cake.

5. Cake Discharge and Belt Cleaning

The final dewatered sludge cake is removed from the belt and collected, while automated cleaning systems spray wash the belts for the next cycle.

Key Advantages of Belt Presses

Belt press for sludge dewatering offers:

- Continuous operation — Ideal for facilities requiring consistent sludge handling.

- Lower energy consumption — More efficient than thermal or centrifuge-based methods.

- Compact footprint — Suited for facilities with limited space.

- Ease of maintenance — With fewer moving parts and accessible components.

- Customizability — Suitable for different sludge types and feed volumes.

Hesheng Filter's Belt Press Solutions

Hesheng Filter offers two high-performance models to meet a wide range of application needs:

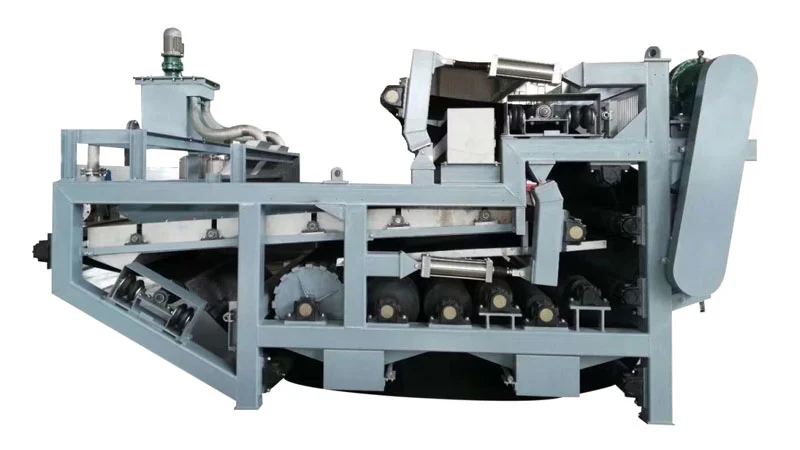

SPF Tower Filter Press

- Vertical Stacked Design: The tower filter press maximizes space efficiency and leverages gravity for enhanced dewatering performance, with guide devices ensuring stable plate movement.

- All-in-One Operation: Combines filtration, squeezing, washing, air drying, automatic cake discharge, and cloth washing in a single compact unit.

- High-Pressure Performance: Delivers squeezing pressure up to 1.6 MPa, adaptable for processes requiring customized cake moisture levels.

- Energy Efficient & Stable: Hydraulic drive system reduces energy consumption while maintaining reliable, low-noise operation.

- Smart Automation: Integrated PLC, HMI, and instrument controls ensure precision, safety, and ease of use.

- Wide Application Range: Especially suitable for municipal sewage, organic sludge, food waste, and pulp & paper industries.

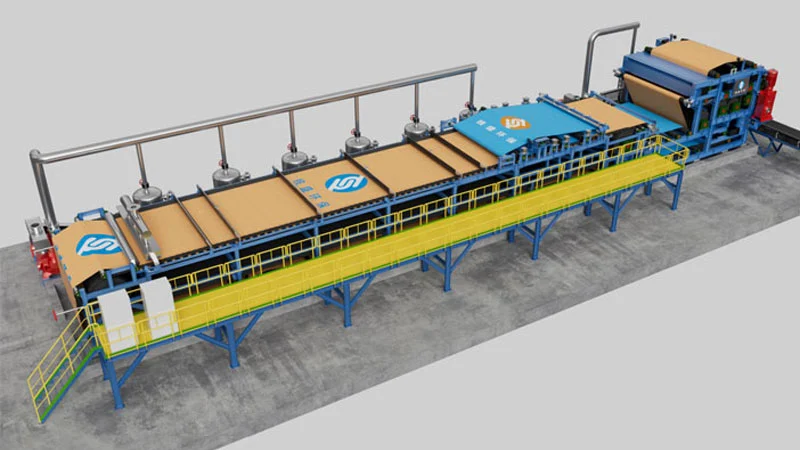

DWY Horizontal Belt Press Filter

- Horizontal layout for higher throughput and easier belt access.

- Multi-zone pressing for superior cake dryness.

- The horizontal belt press filter is commonly used in textile, chemical, mining, and tannery industries.

Common Applications

Hesheng Filter's belt press solutions are suitable for a wide range of industries, including:

Municipal Wastewater Treatment: Efficiently dewatering sewage sludge to reduce disposal costs.

Pulp and Paper Industry: Managing fibrous sludge generated during paper production.

Food and Beverage Processing: Handling organic waste and byproducts effectively.

Mining and Mineral Processing: Dewatering mineral slurries for easier handling and disposal.

Chemical Manufacturing: Treating various chemical sludges and byproducts.

If you're looking for a sludge dewatering system that combines efficiency, reliability, and cost-effectiveness, a belt press for sludge dewatering from Hesheng Filter is the smart choice. Whether you need a vertical or horizontal configuration, our team will help you find the ideal solution for your operation.

Hesheng Filter

Hesheng Filter