Filtration is a critical process across a wide range of industries—from wastewater treatment and chemical manufacturing to mining and food processing. At Hesheng Filter, we specialize in high-efficiency filter press systems designed to optimize solid-liquid separation with minimal energy and maximum reliability.

If you're exploring industrial filtration solutions, this guide explains everything you need to know about how filter presses work and why Hesheng Filter's innovative technology stands out.

What Is a Filter Press?

A filter press is a powerful tool used to separate solids from liquids in slurry mixtures. It operates on the principle of pressure filtration, pushing liquid through filter media to leave solid particles behind as a dry cake.

Widely used in sludge dewatering, chemical refining, and industrial wastewater treatment, filter presses are essential for reducing waste volume and improving fluid recovery.

How Does a Filter Press Work?

The filter press process consists of several key stages:

1. Slurry Feed

A slurry mixture is pumped into the press chambers, which are formed by a series of filter plates lined with filter cloth.

2. Pressure Filtration

As the feed pump continues, pressure builds inside the press, forcing liquid through the porous cloth and out through the discharge channels. The solids are trapped and accumulate on the cloth surface, forming a filter cake.

3. Cake Formation

Over time, the thickness of the filter cake increases until the chamber is full. At this point, filtration slows and the press cycle ends.

4. Cake Discharge

The plates are opened, and the dry filter cakes drop off—ready for disposal or further processing.

5. Cleaning and Repeat

Filter cloths are cleaned as needed before the cycle starts again.

Pro Tip: Filter press performance can be optimized by adjusting cycle time, pressure, feed rate, and cloth type—Hesheng Filter offers technical support to help you get it right.

Types of Filter Presses by Hesheng Filter

Hesheng Filter provides three specialized filter presses, each engineered for specific needs. Here’s an in-depth look at each:

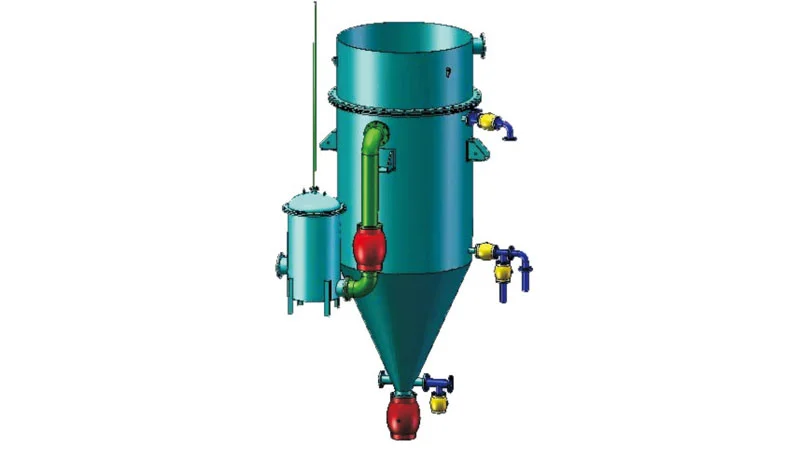

SPF Tower Filter Press

The SPF tower filter press is a cutting-edge, energy-efficient solution for solid-liquid separation. Its vertical tower design uses slurry feed pressure and rubber membrane squeezing to deliver exceptional results.

Key Features:

Vertical Stacked Design: Ensures stable operation with guide devices.

All-in-One Functionality: Integrates filtration, squeezing, washing, air drying, cake discharge, and cloth washing.

High Pressure: Up to 1.6 MPa for customizable cake moisture levels.

Energy Efficient: Hydraulic controls minimize power usage.

Smart Automation: PLC and HMI enable precise operation.

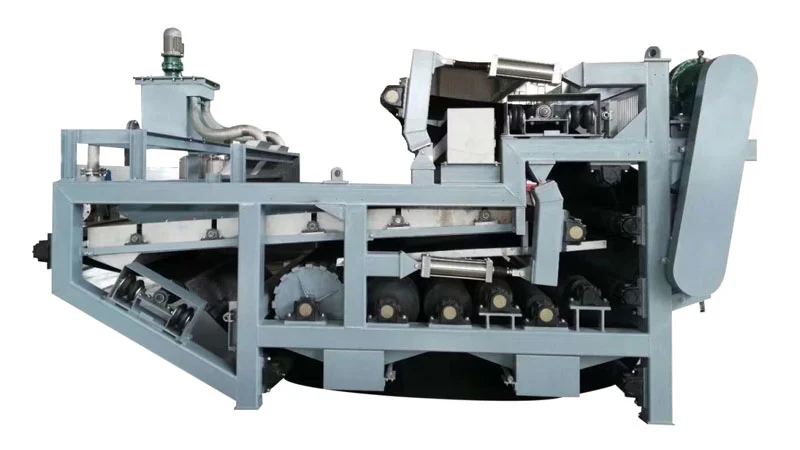

DLY Vertical Belt Press Filter

The DLY belt filter press for sludge dewatering delivers high efficiency and a compact design, making it ideal for wastewater and industrial applications.

Key Features:

Space-Saving: Vertical design fits tight spaces.

Superior Dewatering: Processes large sludge volumes with low moisture cakes.

Robust Build: Suited for continuous operation in tough conditions.

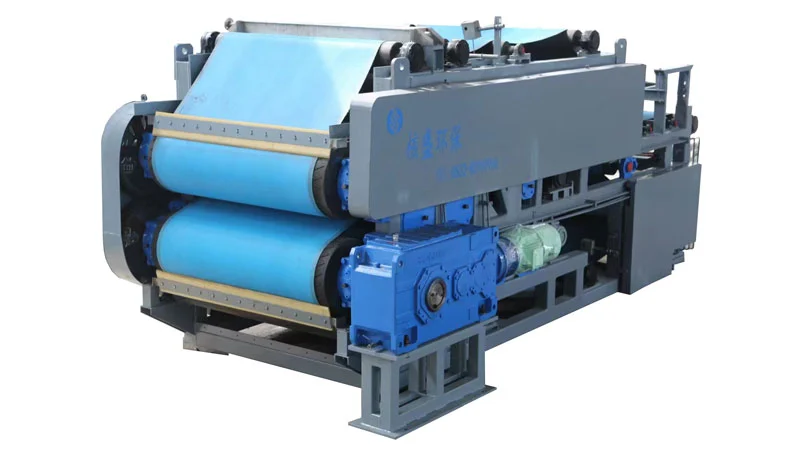

DWY Horizontal Belt Press Filter

The DWY Horizontal Belt Press Filter is a versatile option, ideal for dewatering diverse materials. Its S-shaped belt design applies gradual pressure for optimal performance.

Key Features:

S-Shaped Belt: Reduces wear and enhances belt longevity.

Material Flexibility: Handles organic and inorganic substances.

Easy Maintenance: Horizontal layout simplifies upkeep.

Why Choose Hesheng Filter?

With over two decades of experience in industrial filtration, Hesheng Filter is your trusted partner for reliable, custom-engineered filter press systems.

Key Advantages:

Customized designs for your specific industry needs

Automation-ready systems to reduce labor and increase consistency

Durable components and long-lasting filter media

Expert support for installation, operation, and optimization

Applications of Filter Presses

Wastewater Treatment Plants

Chemical & Petrochemical Plants

Mining and Metal Processing

Food & Beverage Production

Textile Dyeing and Finishing

Pharmaceutical Manufacturing

Hesheng Filter's SPF Tower Filter Press, DLY Vertical Belt Press Filter, and DWY Horizontal Belt Press Filter deliver tailored solutions for solid-liquid separation. Whether you're in mining, chemical processing, or wastewater management, our equipment enhances productivity and reliability.

Contact our experts today at www.heshengfilters.com for customized advice and a free project evaluation.

Hesheng Filter

Hesheng Filter